BASF’s Styrofan 7809, a revolutionary back tile bonding primer, has emerged as the best tile adhesive for walls in modern interior design. As the demand for larger porcelain tiles continues to grow, traditional adhesive methods struggle to provide a secure and long-lasting bond. Ceramic tiles are a popular choice for various areas such as bathrooms, kitchens, lobbies, and staircases, but these larger, less water-absorbent tiles pose unique challenges in terms of installation and longevity, increasing the risk of detachment over time.

Traditional tile adhesives often struggle to maintain a strong and lasting bond with larger, less porous porcelain tiles. Multiple environmental factors can contribute to tile detachment, including temperature variations between day and night or seasonal changes, exposure to high heat in areas like kitchens, and contact with water in bathrooms or showers. These conditions can cause movement in the substrates and adhesives, leading to adhesion failure and eventual tile detachment. Furthermore, vibrations in high-traffic areas like lobbies or staircases can further exacerbate the problem, causing tiles to become loose and potentially fall, posing safety risks and requiring costly repairs.

Cementitious tile adhesives, commonly used for tile installations, have inherent limitations when it comes to bonding with larger, non-porous tiles. Despite employing thicker application methods to increase adhesion, the lack of sufficient polymer content at the bonding surface remains a fundamental issue. Polymers are the key components responsible for forming strong adhesion between the tiles and substrates, but traditional cementitious adhesives often fail to concentrate adequate polymers at the critical bonding interface, leading to poor adhesion and an increased risk of tile detachment over time.

To address these challenges, a new and innovative solution has emerged in the form of back tile bonding primers. These primers are designed to concentrate polymers at the bonding surface between the tile and the adhesive, effectively promoting superior adhesion and secure tile installation. By applying a thin layer of the primer directly to the back of the tile, a highly concentrated polymer-rich interface is created, ensuring a strong and long-lasting bond that can withstand environmental factors and vibrations.

Leading the way in this innovative approach is BASF’s Styrofan 7809, a state-of-the-art back tile bonding primer that offers exceptional performance and durability. Designed specifically for larger porcelain tiles, Styrofan 7809 leverages advanced polymer technology to create a robust bond between the tile and the adhesive. Its key features include enhanced adhesion strength, superior water resistance, and remarkable resistance to temperature fluctuations, ensuring that your tile installation remains secure and intact under various environmental conditions.

To truly understand the superior performance of BASF’s Styrofan 7809, it’s essential to put it to the test against traditional adhesive methods. One widely accepted test in the market is the hammer test, which evaluates the impact resistance of different tile installation methods.

In this test, tiles installed with traditional methods without a back tile bonding primer were easily knocked off in just a few seconds, with large pieces dislodging from the surface. However, when Styrofan 7809 was applied as a back tile bonding primer, the results were remarkably different. The tile showed outstanding resistance to hammering, with only small pieces chipping off at a time, and it took a significantly longer duration to completely remove the tile.

These results clearly demonstrate the increased impact and vibration resistance provided by Styrofan 7809, ensuring that your tile installations remain tightly fastened and reliable, even in high-traffic areas or under challenging conditions.

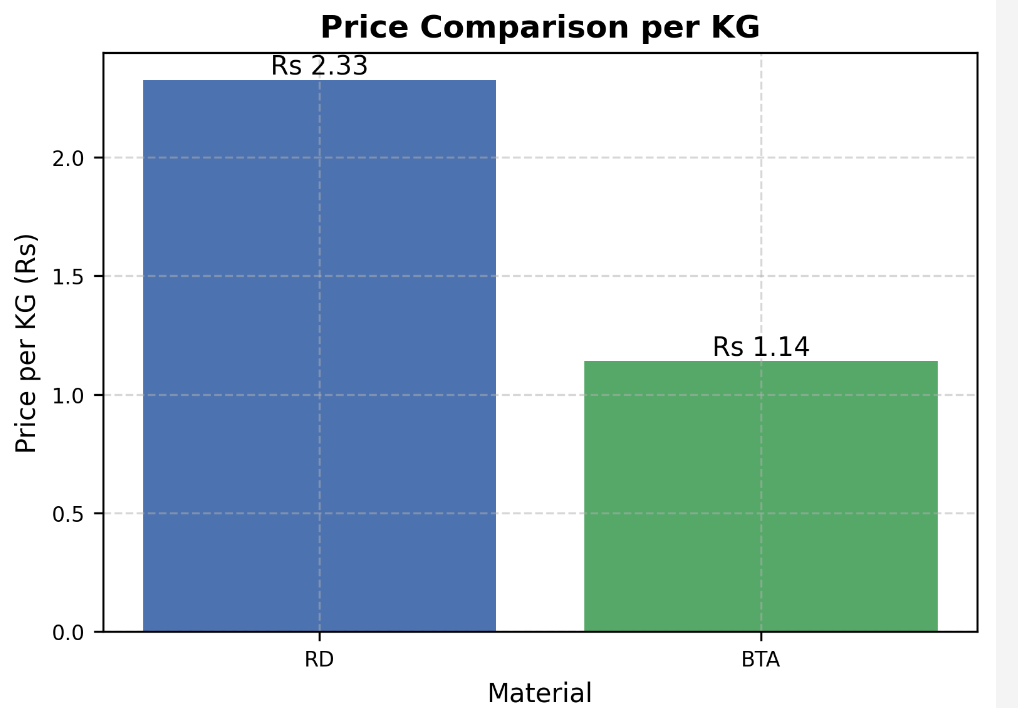

In addition to its superior technical performance, BASF’s Styrofan 7809 offers a cost-effective solution for tile installations. Compared to traditional methods using RD powder adhesives, Styrofan 7809 can significantly reduce material costs.Under common conditions, with a 6 mm tile adhesive thickness and 1.5 RD powder typically used, the use of Styrofan 7809 can save up to Rs. 1.2 per kilogram, translating to a savings of approximately Rs. 24 for a 20 kg bag.

To help you better understand the potential cost savings, we have created a user-friendly calculator that takes into account your specific project requirements. By entering details such as the tile size, area coverage, and other relevant factors, the calculator will provide a detailed comparison of the costs associated with using Styrofan 7809 versus traditional RD powder adhesives.

Calculate your savings.

This cost-saving advantage, combined with the reduced need for tile replacements and repairs due to its exceptional bonding strength, makes Styrofan 7809 an economically viable choice for both residential and commercial projects. We encourage you to explore our cost calculator and discover the potential savings that BASF’s innovative back tile bonding primer can offer.

CONTACT 9426104316 for more details.